Phat Trakka

Part 4: Does it measure up?

Still with me? Good. The basic idea was to create a low, fat, fast street tracker out of an obese, underpowered GT750. Already in the workshop were a pair of 2002 GSXR-750K2 forks and a set of slightly older GSXR fat wheels, GSXR-600K2 swingarm and nice clean low mileage GSXR1000-K2 shock and linkage - all bought for the first bike.

The main parts were loosely bolted together just to see what would work and what wouldn't.

Then a set of All Balls taper roller bearings for the steering head, bought for that first bike, and by some quirk of nature, they have the right bore to fit the GSXR stem and the right OD to suit a GT750 Steering head.

That RS250 Aprilia Cup bike seat almost looks sexy back there, but not for the Phat Trakka. This bike needed a flat track type seat and Gordon, one of the helpful guys on Sundial, had a spare used one for which a small number of drinking vouchers were exchanged. Things were headed in the right direction already.

Everything looked like it might just work until I started to measure things up properly, but it was looking mighty tall at the rear, and that was not in the plan.

Math Time

OK class, what happens when you slip a 4 inch longer swingarm into a bike that's already too long in the wheelbase. Correct. It becomes even longer. Mmm. I didn't plan on shortening the swingarm, so this bike will be really stable in a straight line. Just like an early Ducati. See. It was intentional.

But the plan was for more modern steering geometry with say 10 or 11 degrees of swingarm droop and say 25 degrees of rake. A On the mock up, 11 degrees of droop actually raised the swingarm pivot point by about 4 inches! That can't be right. Let me see if I can remember high school mathematics.

A triangle with included angle of 11 degrees with Hypotonuse of 22.5 inches has the opposite side how long?

Sin (11degrees) = Opp/Hyp

therefore, Opposite = Hyp x Sin (11)

or = 22.5 x .1908

= 4.29 inches.

That would raise the seat by 4 inches and would make the steering very steep. The good news is that compared with a flat horizontal swingarm, the wheelbase would be 0.4 inches shorter.

That wasn't a lot of good news.

Well that wasn't going to work, so let's try 8 degrees. That would raise the pivot by only 3.1 inches. Slightly better. 6 degrees raises it by only 2.35 inches, and 4 degrees would be 1.5 inches. Time to stop the theory and get on with the job.

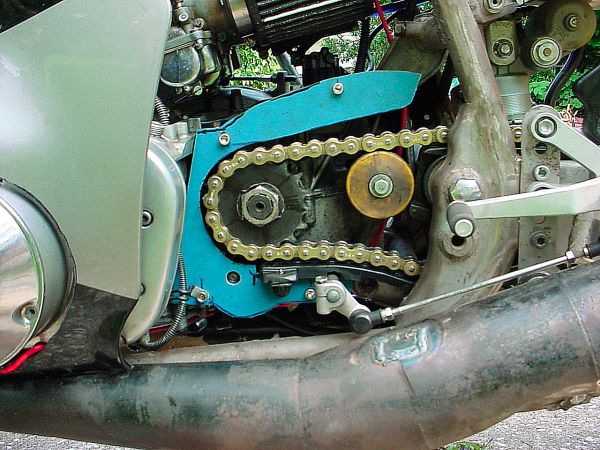

At that point, I seriously looked at the possibility of machining out the swingarm pivots and welding them in about an inch or so higher to bring the frame back to a more even keel, but decided that was way too complicated. Of course, that would in turn require the motor to be raised by about the same amount to get the chain line back into some degree of normalcy.

At that point it also became clearer what was needed on Suzukidave's GTXR and to the Tim's Mighty Buffalo.

|

Tim and Dave found the same problem and came up with similar solutions. I haven't decided how I'll compensate for this problem yet, but I suspect I'll travel down the same path.

Meanwhile, back at the front end, the USD GSXR forks were much shorter than stock and the 17 inch GSXR wheel was decidedly smaller than a stock 19 inch rim, so something needed to be done to make it all work. It may be necessary to lift the front end to compensate for the shorter forks. Three alternates are, get fork extenders machined, use Race-Tech extenders, use a CBR954 triples , or cut the steering head off and weld it back on lower and at a different angle - something I would rather avoid, or get custom triple clamps made.

Commitment time

All the measurements taken so far were very approximate, just to get some idea of what the engineering issues were and to identify alternate strategies to satisfy the design brief. As soon as the swingarm spindle and spacer come back from the machine shop, the monster will go back together for more accurate measurements so that shock mounts can be designed and fabricated.

Other people have built these abominations, so at this stage, I will assume that any engineering issues can be overcome, so while the swingarm pivot is away at the machine shop, it's time to fire up the angle grinder........

Part 4a: The angle of the dangle..